Lamp Models — Diagnostics, Lamps, Ballasts, Cooling, Optics & Colour

We specialise in Christie lamp-based projectors across LW/LHD/LWU, Roadster/Roadie and legacy 1DLP families. Our engineers triage power, thermal and optical paths, then restore performance with documented, accountable repairs.

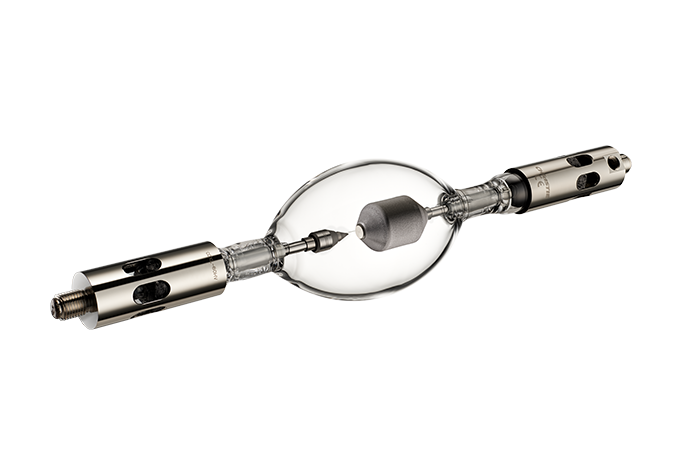

UHP & Xenon lamps — supply, fit and alignment

UHP and Xenon lamps age differently. UHP capsules gradually lose output and shift colour temperature; Xenon can maintain colour but suffer arc instability or noisy ballast starts near end‑of‑life. We evaluate the lamp in‑situ by measuring strike voltage, warm‑up behaviour and real‑world brightness rather than relying on counters alone.

Our intake checks include: verifying lamp hours against logs, inspecting connectors and HV boots for carbon tracking, checking lamp housing seals, and confirming door/cover interlocks. When installing a replacement, we clean the reflector path, fit the lamp to torque, and re‑index alignment where the optical design allows.

Results you should expect: predictable starts, stable brightness, improved white balance and reduced risk of collateral damage to the ballast or ignitor from repeated mis‑strikes.

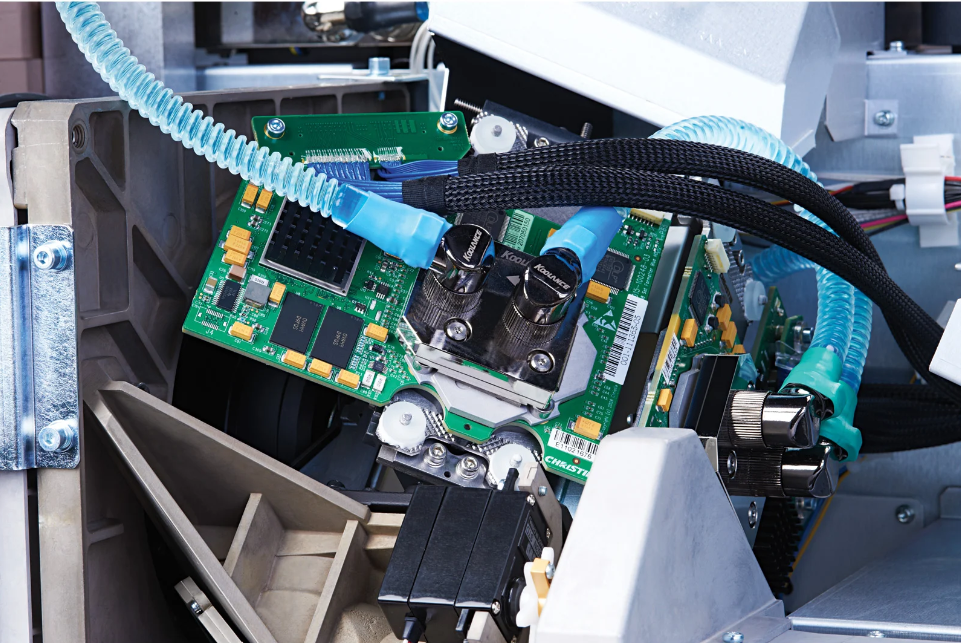

Ballast and ignitor service — reliable starts, lower stress

Mis‑strikes and hard starts point to aging components in the ballast/ignitor chain: IGBTs, electrolytics, diodes, transformers and the HV leads themselves. We scope DC bus ripple, verify charge/discharge timing, and inspect for heat stress or cold solder joints. Where economical, we refurbish; otherwise we replace with Christie‑approved parts or proven equivalents.

We also review mains quality and installation: poor line regulation or frequent on/off cycling dramatically reduces lamp and ballast life. Our report includes practical operational changes to extend service intervals.

After service we perform cold and hot strike tests and log strike voltage, current and time‑to‑lumen‑stability to evidence reliability.

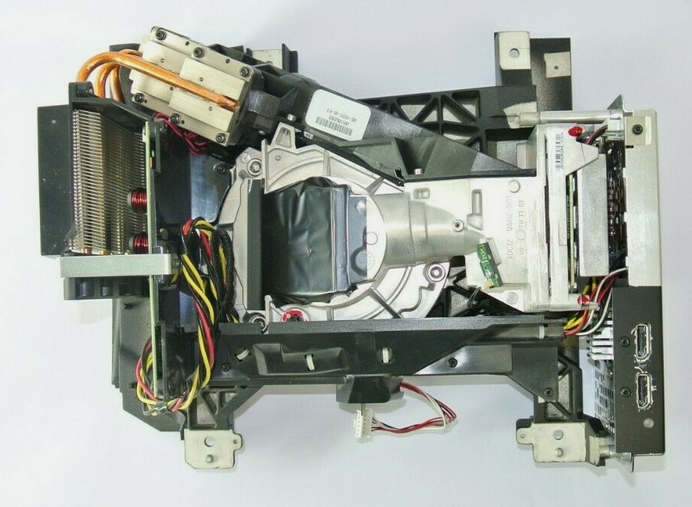

Cooling path rebuild — airflow proven before return

Thermal throttling is a hidden performance killer. Clogged filters, tired blowers and dried thermal interfaces raise junction temperatures, forcing shutdowns or dimming. We deep‑clean ducts, replace filters and worn fans, renew TIMs where accessible, and verify sensor behaviour (NTCs/thermistors) with controlled heat loads.

For staging units we also audit the venue’s airflow constraints and recommend dust‑mitigation steps. All units leave with validated fan RPM, stable thermal curves and error‑free operation at typical ambient temperatures.

The outcome: fewer thermal warnings, consistent brightness and lower acoustic noise under load.

Optics cleaning & reseal — restore contrast and uniformity

Dust and residue on integrators, mirrors and prisms reduce contrast and introduce colour casts. We use lint‑free techniques and approved solvents to clean accessible optics, then reseal carefully to limit future ingress. On 1DLP units we can service colour wheels and rebuild light tunnels where collapse is evident.

We finish with a uniformity and focus audit across the screen, correcting mechanical tilt or alignment where possible within the manufacturer’s tolerances.

Expected benefit: sharper images, improved black levels and consistent colour across the field.

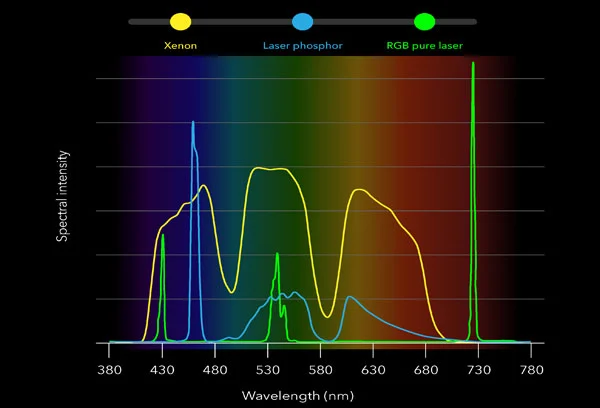

Colour calibration & matching — proof on paper

Once hardware is stable, we calibrate brightness, gamma, greyscale and colour primaries to your target (e.g., Rec.709 or venue preference). For multi‑projector arrays we match white point and balance output so blends are seamless.

We document pre‑ and post‑repair measurements and provide a concise calibration sheet with target values and tolerances. This makes future swaps and client sign‑off straightforward.

For rental fleets, we can create a repeatable “golden” profile per model to keep colours consistent across inventory.